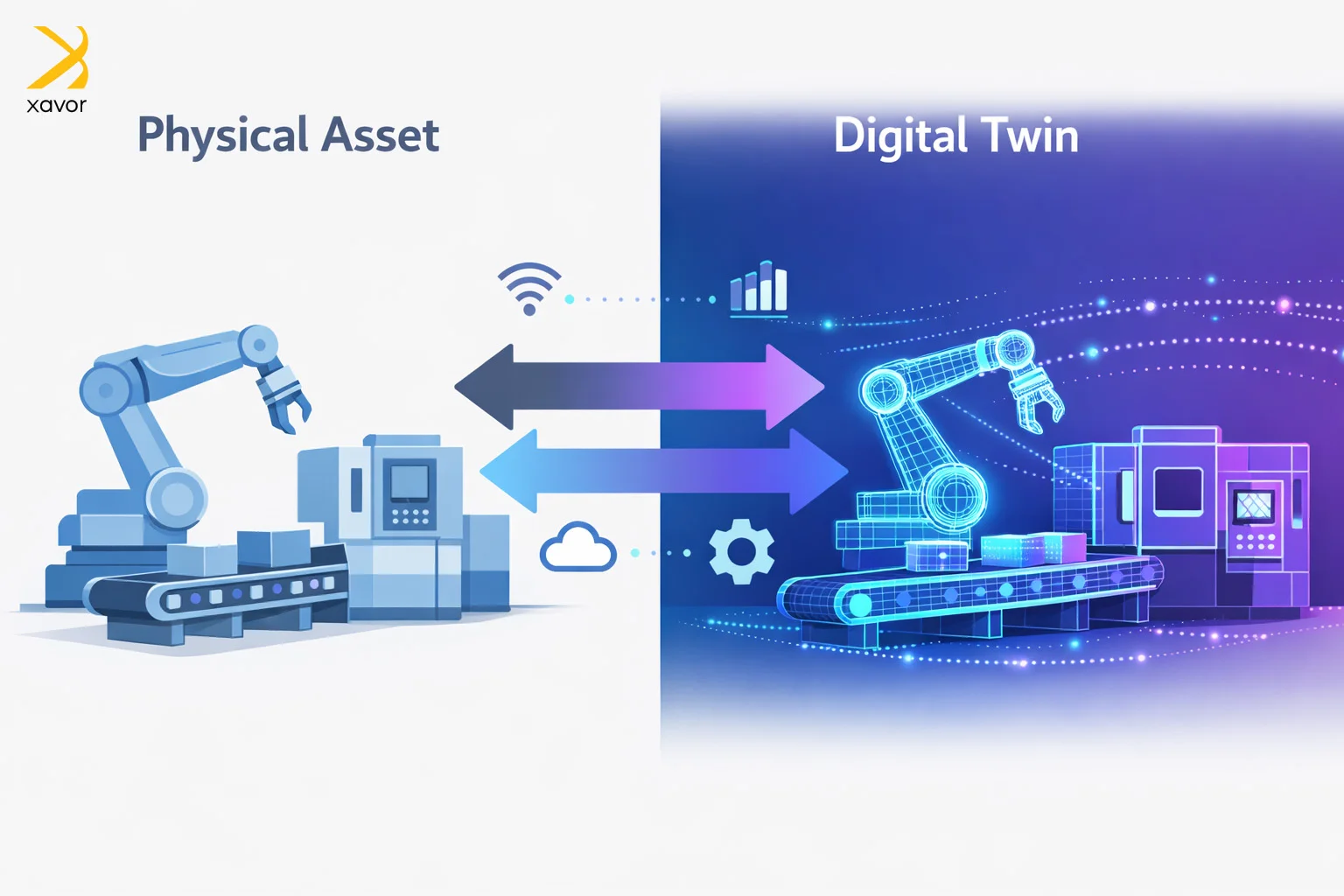

Manufacturers are increasingly adopting digital twins and Physical AI solutions. A digital twin is a real-time virtual model of a physical asset, product, or process. It helps teams monitor performance, evaluate conditions, identify issues early, and improve operations more effectively.

McKinsey notes that with a strong digital twin platform, companies can run full product simulations in a virtual environment before the customer approves the final design. This highlights why digital twins are gaining traction in manufacturing.

Digital twins are also improving product development. By replicating real systems digitally, organizations can work faster, make better decisions, increase productivity, and reduce costs by addressing problems earlier in the cycle.

Market growth reflects this momentum. Grand View Research reports that the digital twin market was valued at $16.75 billion in 2023 and is projected to reach $155.84 billion by 2030, with a CAGR of 35.7% from 2024 to 2030. With growth like this, digital twins are expected to play an even larger role in manufacturing in the coming years.

Now, let’s explore the key benefits of digital twins and the most impactful use cases driving their adoption.

What are digital twins?

In manufacturing, a digital twin is a virtual representation of a real system, machine, or process. It works like a detailed digital model of a factory floor, built to reflect real operating conditions and predict how changes may affect outcomes.

Manufacturing teams use digital twins to plan, study, and improve processes in a simulated environment. This allows them to test ideas and optimize performance without relying on costly physical trials or disrupting work on the shop floor.

History and evolution

Digital twins began with CAD tools, which enabled engineers to create detailed digital drawings and models of real objects. As computers became faster and sensors became more advanced, these simple models evolved into smart simulations that could update in real time using real-time data.

By the early 2010s, digital twins became popular in industries such as aerospace and automotive because these fields deal with complex machines that require very high accuracy and reliability.

A breakthrough happened when NASA began using digital twins to track and maintain spacecraft. This helped NASA keep spacecraft safe and working properly in the tough conditions of space. NASA’s success demonstrated how powerful digital twins can be, and more industries began using them as well.

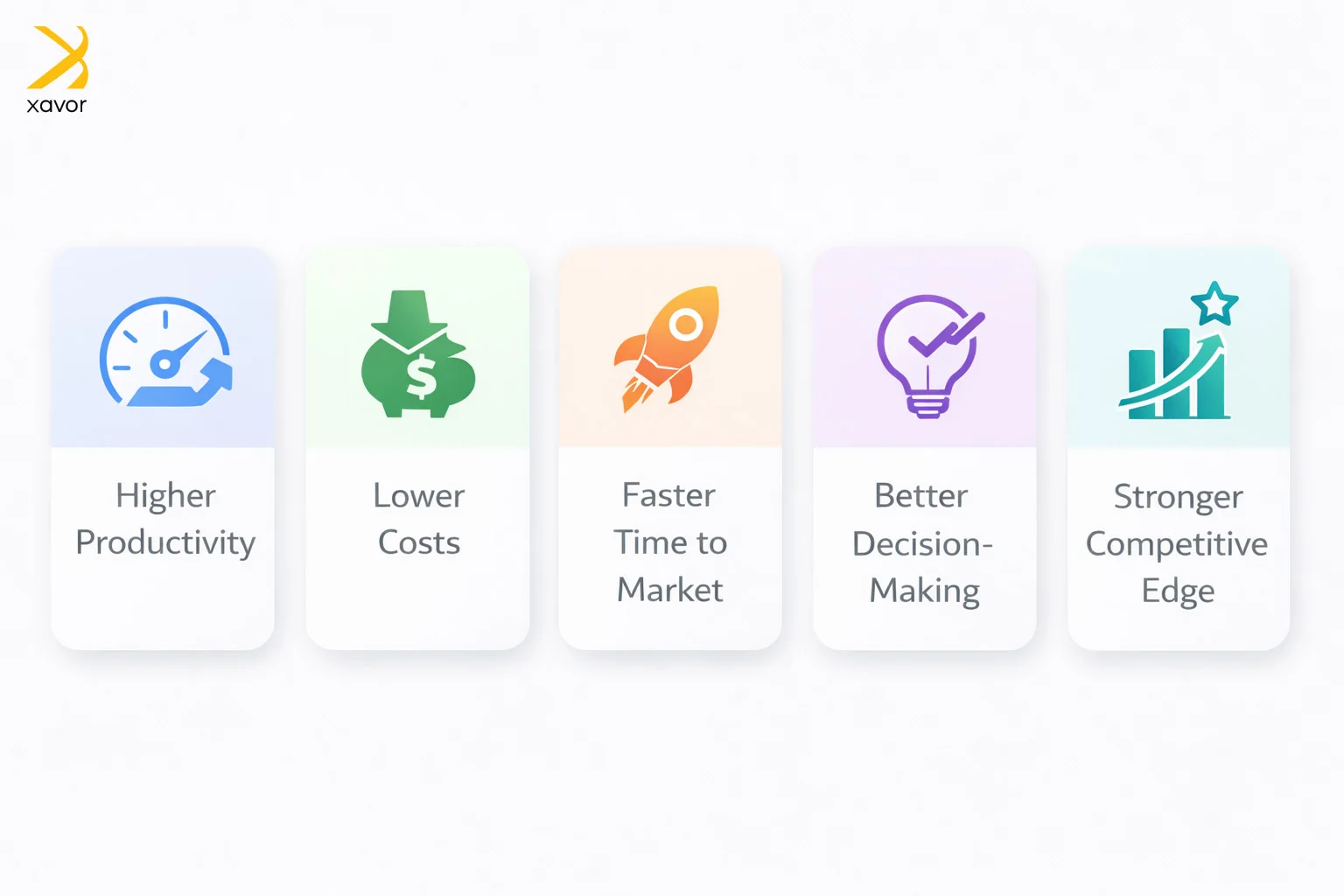

Digital twins benefits in manufacturing

1. Higher productivity

Real-time virtual models help identify inefficiencies early. Teams can test process improvements in a simulated environment. This reduces downtime and increases overall output.

2. Lower costs

Live monitoring supports better maintenance planning. Predictive insights help prevent failures before they disrupt production. Less waste and fewer breakdowns lead to meaningful cost savings.

3. Faster time to market

Virtual prototyping makes it easier to validate designs quickly. Product changes can be tested before any physical build begins. This shortens development cycles and speeds up launches.

4. Better decision-making

Accurate operational data improves visibility across systems. Analytics highlight performance trends and potential risks. Leaders can act faster with clearer, data-backed directions.

5. Stronger competitive edge

Greater agility helps manufacturers respond to shifting demands. Continuous optimization improves efficiency over time. A future-ready approach supports long-term growth and resilience.

Digital twins in manufacturing: Top use cases

Digital twins are helping manufacturers understand their operations more clearly. They create a digital version of a real machine, product, or process. This makes it easier to track performance and find problems that might be missed otherwise. Once the issue is visible, teams can simulate different digital manufacturing solutions and choose the best one. That approach reduces guesswork and supports better results.

1. Predictive maintenance and reduced downtime

One of the strongest applications of digital twins is predictive maintenance. Unlike reactive maintenance, which causes expensive unexpected stoppages, or preventive maintenance, which can lead to replacing parts too early, digital twins continuously track equipment behavior and forecast issues before breakdowns happen.

Example: A consumer electronics company used digital twin models to evaluate a new product’s aerodynamics and heat dissipation. The insights helped optimize the design 20% faster, lowering development costs and improving reliability.

2. Virtual prototyping and smarter product design

Building new products the traditional way often requires multiple physical prototypes, which adds cost and time. Digital twins transform this process by enabling virtual prototypes and realistic simulations long before any physical build is required.

Example: A consumer electronics company applied digital twin simulations to test a new product’s aerodynamics and thermal performance. This accelerated design refinement by 20%, reducing costs while boosting product durability.

3. Smart factory and process optimization

Manufacturers use digital twins to fine-tune production lines and strengthen operational performance. By continuously evaluating machine output, material movement, and energy usage, digital twins enable real-time process adjustments and increased productivity.

Example: A global food processing firm implemented digital twins to simulate and improve packaging-plant workflows. By spotting bottlenecks before making on-site changes, the company increased production output by 15% without investing in new infrastructure.

4. Remote monitoring and control for distributed operations

As manufacturing becomes more global, remote visibility and control are increasingly important. Digital twins enable teams to oversee multiple sites from anywhere, improving coordination, consistency, and operational continuity.

Example: A pharmaceutical company monitored global production sites through digital twins. When a problem surfaced at a distant facility, engineers made real-time remote adjustments to maintain quality and compliance without being on-site.

5. Supply chain resilience and logistics optimization

Supply chain efficiency, getting hindered due to disruptions, is a persistent challenge in manufacturing. Digital twins help by simulating logistics, inventory, and supplier performance in real time, enabling teams to anticipate risks and respond more quickly when disruptions occur.

Example: A multinational automotive company used a digital twin of its supply chain to identify alternate suppliers during disruptions. This reduced delivery delays by 40% during a global crisis.

6. Sustainability and energy efficiency

Digital twins play a key role in cutting environmental impact and meeting sustainability targets. By monitoring energy use, material consumption, and waste, manufacturers can make data-backed decisions that reduce emissions and improve efficiency.

Example: A semiconductor manufacturer used digital twins to optimize cleanroom energy consumption across fabrication facilities. Dynamic HVAC and filtration adjustments based on real-time conditions lowered energy usage by 18%, reducing costs and supporting sustainability goals.

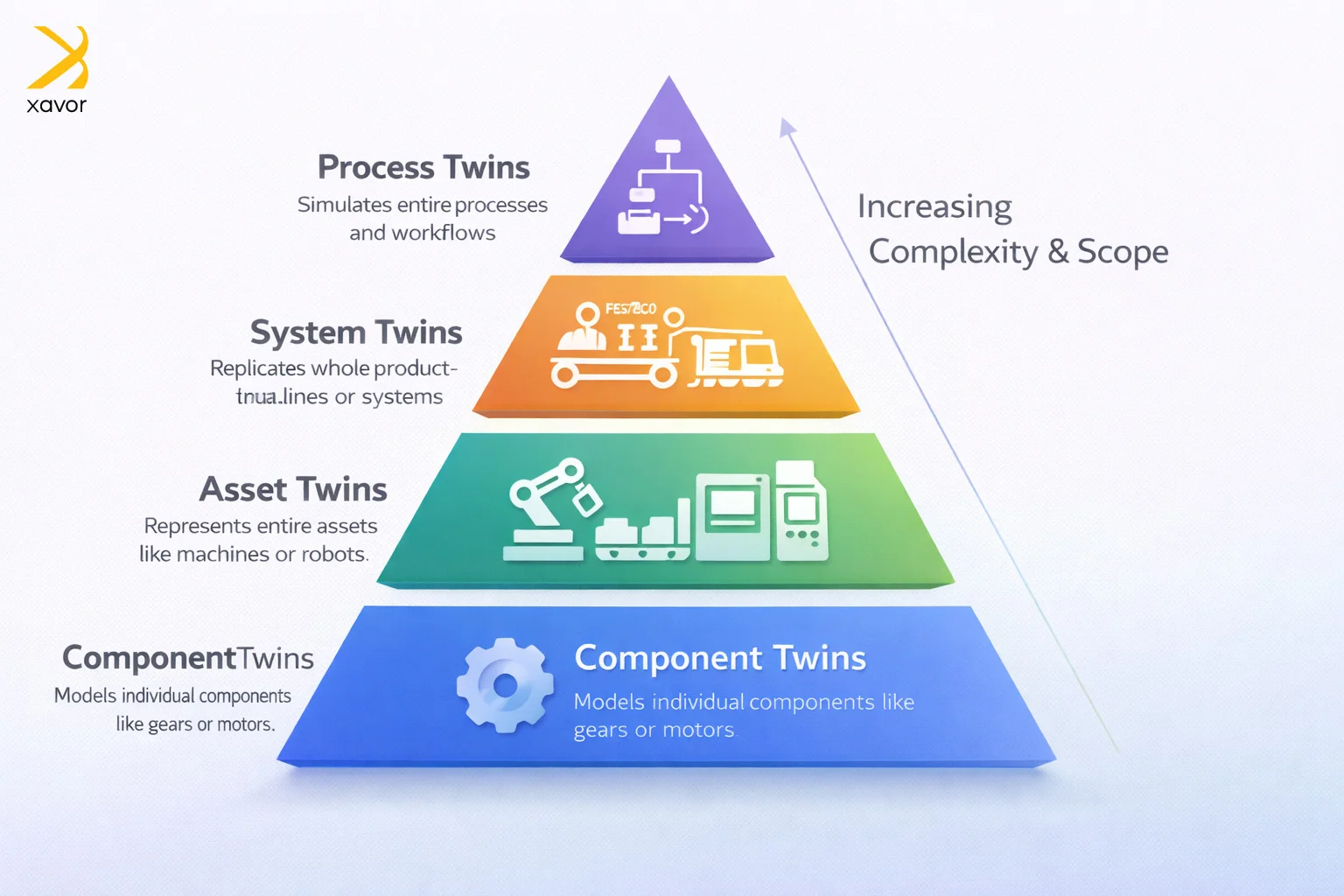

What are the different types of digital twins?

Digital twins come in different types, depending on what you want to model. Each type focuses on a different level in manufacturing, from small parts to full processes.

1. Component twins (Parts twins)

These are digital copies of single parts or components. They help you understand how one part performs, how long it will last, and how to improve its design and quality.

2. Asset twins

These are digital copies of machines or devices. They help companies monitor equipment in real time, find problems early, and improve performance using predictive maintenance.

3. System or unit twins

These are groups of machines working together, such as a full production line. They help you see how different machines interact and where delays or bottlenecks occur.

4. Process twins

These simulate the full manufacturing process from start to finish. Companies use them to test different scenarios, improve workflows, and optimize operations without disrupting real production.

Each type is useful for a specific purpose, whether it’s improving a part, keeping machines running smoothly, speeding up production lines, or optimizing the entire process.

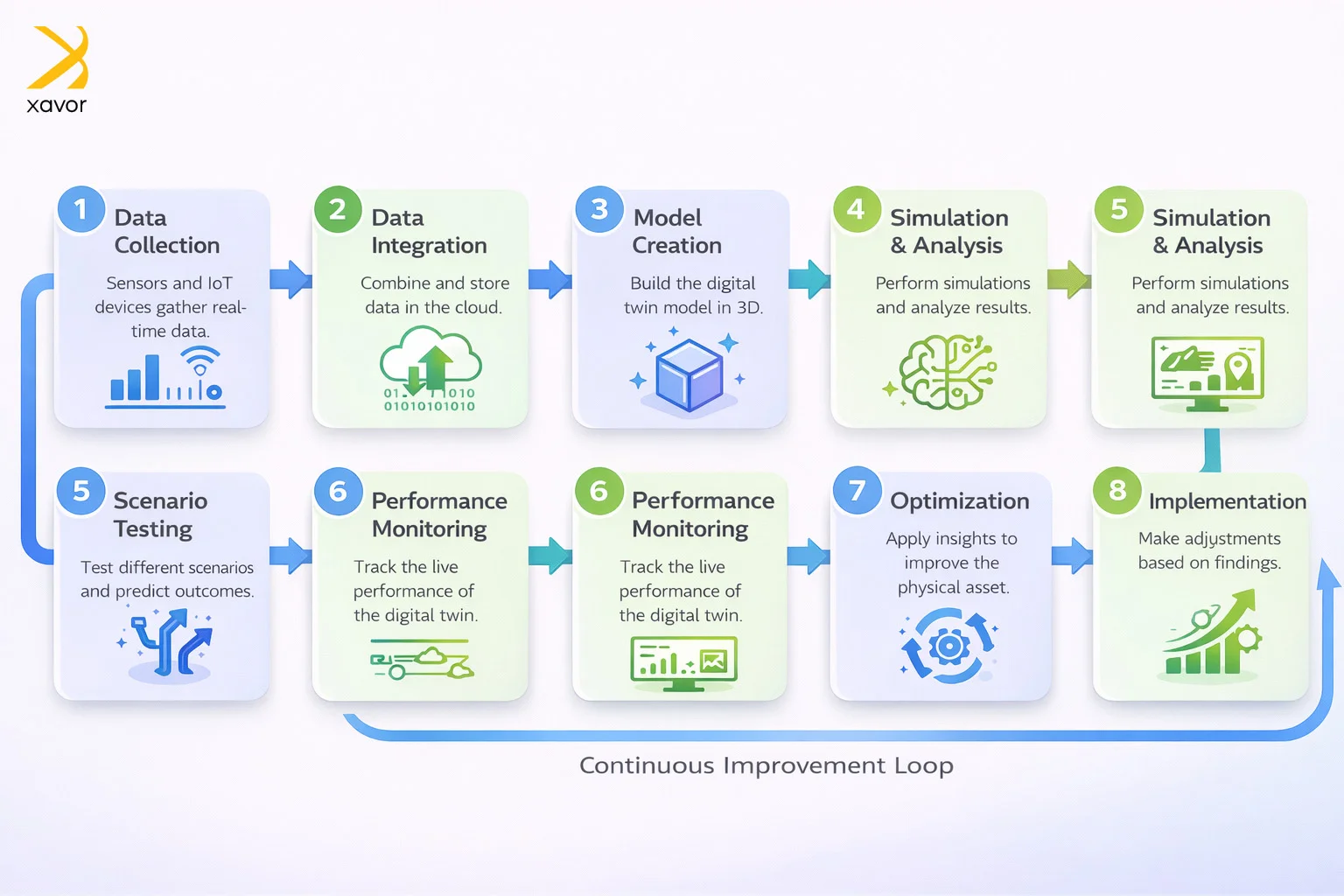

How do digital twins work in manufacturing?

Digital twins work by creating a virtual copy of a real machine or system and keeping it synchronized with live data. Here’s how it happens.

Step 1: Data collection

Sensors are installed on the physical asset to capture key operating data, such as:

- temperature

- pressure

- vibration

- speed

Step 2: Data integration

That sensor data is sent to an IoT platform, which collects it in one place and keeps it available in real time. This is what connects the real asset to its digital twin.

Step 3: Digital model creation

Software then builds a virtual model of the asset using the incoming data. The model updates continuously, so it always matches what’s happening in the real world.

Step 4: AI and machine learning

AI tools analyze both historical and live data to:

- spot patterns

- predict future performance

- warn about possible issues early

Step 5: Simulation and prediction

The digital twin can run “what if” tests to predict failures and find better ways to operate. This helps plan maintenance before breakdowns happen and reduces downtime.

Step 6: Visualization and user interaction

A well designed dashboard makes the digital twin easy to use. It lets teams monitor performance, view results clearly (often with 3D visuals), and explore simulation outcomes.

Step 7: Feedback loop

The physical asset and digital twin continuously share information. The real asset updates the twin, and the twin provides insights that improve real operations.

Step 8: Continuous improvement

Over time, companies use the digital twin to find inefficiencies, test improvements virtually, and apply the best changes in the real system.

Digital twins in manufacturing companies

1. Tesla

Tesla uses digital twin technology to improve factory operations and vehicle performance. Each Tesla vehicle is paired with a digital twin that collects data throughout its lifecycle, from production through everyday driving. That information supports design improvements, helps anticipate maintenance needs, and contributes to a better ownership experience.

2. BMW

BMW uses digital twin technology to strengthen its vehicle manufacturing operations. These virtual models simulate assembly-line activity, enabling teams to refine workflows, improve precision, and boost efficiency. As a result, BMW can reduce production errors and maintain higher, more consistent build quality.

This also applies digital twins to test vehicle behavior in different driving and environmental conditions. This provides engineers with reliable data to guide safety improvements and enhance the customer experience. Digital twins also support the design and validation of new features and technologies, which shortens development timelines and helps BMW bring innovations to market sooner.

3. General Electric (GE)

GE uses digital twins to monitor and maintain jet engines. Each engine has a virtual model that receives real-time sensor data, tracks performance, and predicts when maintenance is needed. This approach has reduced unplanned maintenance by 40% and increased engine uptime, which leads to fewer disruptions in operations.

GE also uses digital twins to improve fuel efficiency and reduce emissions. The data helps engineers detect early warning signs of wear or performance loss, so they can schedule fixes before a failure occurs. This improves reliability and can extend the service life of each engine.

Conclusion

Digital twins are becoming a key tool in manufacturing because they create a real-time virtual model of assets and operations. This model updates with live data, which helps teams detect problems early and predict failures before downtime happens. It also supports virtual testing, which reduces the need for costly physical trials and speeds up product development.

Over time, digital twins improve productivity and reduce waste. They strengthen decision-making through clearer operational visibility. They also support energy efficiency and help manufacturers stay resilient in supply chain disruptions. If you want to explore how digital twins can improve your manufacturing performance, Xavor can help you plan, build, and scale the right solution. Contact us at [email protected].

FAQs

A digital twin gives manufacturers a real-time virtual view of machines, production lines, or entire processes using live data. This helps teams spot inefficiencies early, predict failures before downtime happens, and test improvements virtually before applying changes on the shop floor.

You typically need sensors (or another reliable data source) to keep a digital twin updated with real-world conditions. AI and machine learning aren’t required to build a basic twin, but they greatly increase value by identifying patterns, predicting failures, and recommending optimizations, especially for predictive maintenance, process improvement, and energy efficiency.

Most manufacturers start where ROI is fastest and data is easiest to collect, such as: 1) Predictive maintenance for critical equipment to reduce unplanned downtime. 2) Process optimization on a bottlenecked production line to improve throughput. 3) Virtual prototyping to validate designs earlier and shorten time to market