For robots to truly replace humans in the real world, they need to mimic the “mechanics” of the human body. The anatomy of the human body is nothing short of a miracle. Will robots ever be able to replicate that 100%? We can’t say it, but it needs to be as real as possible, and that is up to mechanical engineers to achieve.

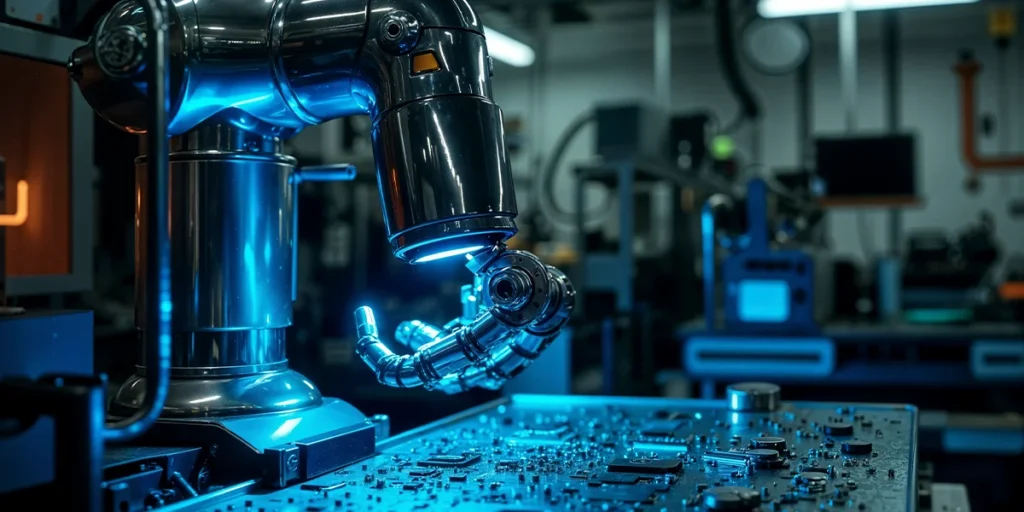

Robots are becoming smarter and more capable than ever, but behind every advanced control system lies a carefully engineered mechanical structure. From lightweight mobile robots to precision robotic arms, mechanical design determines how well a robot performs, how efficiently it moves, and how reliably it operates over time.

While sensors and software often steal the spotlight, a robot’s mechanical design, which is its skeleton, forms the true foundation of performance. Getting that design right means balancing three critical factors: strength, weight, and manufacturability.

However, it is a lot easier said than done. In this blog, we’ll discuss what balanced design really is in robotics solutions, and what the best way is to strike that balance.

Understanding mechanical design for robots

Mechanical design is an indispensable part of various engineering fields. However, the objectives of mechanical design vary. In robotics, the aim is to convert digital intelligence into physical motion. It is analogous to the human body, where our brain sends nerve signals that make our muscles move.

Here is a brief overview of the key aspects involved in mechanical design for robots:

1. Physical forces and motion

Physics underpins everything in robotics and engineering in general. To design a robot that moves correctly, you need to understand how forces affect objects. And for that, you need to master Newton’s Laws.

These laws help you predict how the robot will respond when it applies force, when it accelerates, when it stops, or when it collides.

2. Material choice

Mechanical engineers need to choose the right materials to determine how strong, light, and durable the robot will be. Therefore, metallurgical concepts like yield strength, density, and hardness of materials are considered at every turn.

For example, if a robot is expected to work in an outdoor, humid environment, corrosion-resistance metals like aluminum work best.

3. Structural design

The human construction worker doesn’t bend, break, or deform under physical load. Well, not unless pushed beyond their limits. Robots also need a good structural design to maintain their normal shape while performing physically taxing jobs.

It means that the engineer must design the robot for strength, stress, endurance, and stability.

4. CAD design

CAD (Computer-Aided Design) software lets you create accurate digital models of your robot before you build it. This helps you visualize the design and simulate the robot’s movements before it enters the real world.

Moreover, with technologies like digital thread and digital twin, you can make CAD designs a living model of your robot with pinpoint accuracy.

5. Prototyping

Once you know what your robot looks like on paper, you need to build a prototype to check if your design works as expected. Prototypes test movements, mechanical behavior, and also focuses on the visual look and ergonomics of the robot.

6. Manufacturability

Designing for manufacturability (DFM) is the final step in robotics development. DFM means that your robot will be produced on a mass scale. Therefore, it needs to be easy, cost-effective, and reliable to manufacture and assemble in factories.

A robot that is DFM has simple assembly, uses standardized components, and has the perfect shape that suits the material.

How to achieve balanced mechanical design in robots

Balanced design is a core engineering concept. In civil engineering, it means supporting elements like columns and girders must be stronger than the beams. So that, if a beam breaks, the building can handle it. But if a column fails, whole floors may collapse.

In robotics development, mechanical engineers ensure that the conversion of digital intelligence into physical motion also happens safely and efficiently by designing frames, linkages, and enclosures that can withstand real-world forces and constraints.

However, the challenge lies in achieving the balance between the three critical factors that we mentioned in the intro:

- Strength to handle loads, vibrations, and impacts

- Lightness for improved mobility and reduced energy consumption

- Manufacturability so designs can be built consistently and cost-effectively

Improving one factor usually harms another. For example, making your robot stronger requires a harder material, but that hurts its DFM. To mitigate that, the material must be lighter; however, thin structures are weaker and are often expensive to fabricate. And if you focus solely on making the robot easy to manufacture, it may not fulfill the other two criteria.

So, you see, there are trade-offs everywhere. This three-way balance guides almost every decision, from choosing materials to selecting fabrication methods.

Strength vs weight: Finding the sweet spot

There are many objects in mythology and fiction around that world that could shatter mountains, yet were as light as a feather, such as Thor’s hammer or Poseidon’s trident. Unfortunately, such materials are not known to man as far as science is concerned.

A robot’s frame must be strong enough to support its components and external loads, but every extra gram can reduce range, speed, and efficiency. Therefore, engineers focus on getting the best “strength-to-weight ratio,” meaning maximum toughness from the least amount of material.

There are quite a few techniques out there that you can use to refine this ratio and find that sweet spot between strength and weight.

- Finite Element Analysis (FEA) to simulate loads and identify stress points

- Topology optimization to remove excess material from low-stress regions

- Sheet metal ribs and folds to reinforce stiffness

- Composites or polymer inserts for lightweight, non-structural parts

A well-balanced design can reduce weight by up to 40% while maintaining rigidity — directly improving mobility, battery life, and performance.

Design for manufacturability: Turning concepts into real robots

DFM can also be achieved with the right methods. Using the methods below or tools avoids expensive fixes later and makes the robot ready for industrial-scale production.

Here is a table showing the best manufacturing methods for DFM:

| Manufacturing method | Ideal for | Benefits |

| 3D Printing | Early-stage prototypes, complex shapes | Rapid iteration and testing |

| CNC Machining | Precision parts, motor mounts | High strength and accuracy |

| Sheet Metal Fabrication | Structural frames, chassis | Strong, scalable, lightweight |

Material selection: The backbone of performance

Choosing the right materials for your robot requires a separate guide. After all, the choice of metal is really important to make those shiny robots move with precision. But we’ll discuss that in another blog.

For now, this table will help you make a sensible choice:

| Material | Advantages | Applications |

| Aluminum Alloys | Lightweight, corrosion-resistant | Internal frames, brackets |

| Stainless Steel | Strong, durable | Load-bearing components |

| ABS/Nylon Plastics | Lightweight, printable | Covers and non-structural shells |

| Carbon Fiber Composites | Extremely stiff and light | High-performance mobile robots |

Using the right mix of materials ensures that each part contributes optimally to the robot’s function, cost, and manufacturability.

Component placement and balance optimization

If a single bone in your foot is not in its position, you won’t be able to walk due to discomfort. Robots are the same because even with the best materials and fabrication, poor component layout can compromise performance. The batteries, motors, and sensors in the robot must be placed perfectly; otherwise, the robot will lose its balance.

Optimizing the center of gravity (CoG) improves stability and control, especially in mobile robots. It prevents robots from tipping, especially robots that are meant for mobility, like healthcare robots that continuously monitor patient movement.

These are some of the best practices that you can apply to make your robot stable and easier to control:

- Placing heavier components (like batteries and motors) near the base

- Keeping sensors and controllers accessible for maintenance

- Balancing the CoG between drive wheels or caster points for steady navigation

CAD-based CoG simulations also allow engineers to predict behavior before physical assembly, ensuring smoother operation and reduced strain on actuators.

The prototype to production journey: Iterative robotics development

Mechanical design in robotics is an iterative cycle of digital modeling, prototyping, and real-world validation. Tesla’s Optimus humanoid robot has undergone at least three major generations of iterative development since its announcement.

Follow this step-by-step iterative loop to ensure every structural element directly enables the robot’s goals. This process bridges design intent and functional reality.

1. CAD modeling in SolidWorks

2. 3D printing for rapid prototyping

3. CNC machining and sheet metal fabrication for final assemblies

4. System integration and testing with electronics and sensors

Conclusion

Mechanical engineering is arguably the single most important discipline in deciding the future of robotics. We have electronics and software that can make humanoid robots feasible in the real world. But they still fall short of biological muscles in force density, bandwidth, and control, which limits their nuanced grasping or manipulation capabilities.

However, great progress has been made by leading giants in robotics development to overcome these mechanical challenges. The mechanical design principles and methods that we discussed in this article can help you make a robot that is strong, light, and ready for manufacturing.

At Xavor Corporation, our robotics team applies these design principles daily in developing autonomous mobile robots for elderly care and assistance. These robots are designed to navigate safely, interact intelligently, and support real-world caregiving environments.

With emerging tools like generative design and AI-driven simulation, mechanical engineers at Xavor are helping shape the next generation of intelligent robots — designed not just to function, but to serve humanity with care and precision.

To talk to our robotics team, drop us a message at [email protected], and we’ll get back to you in 24–48 hours.